|

|

|

|

|

|

|

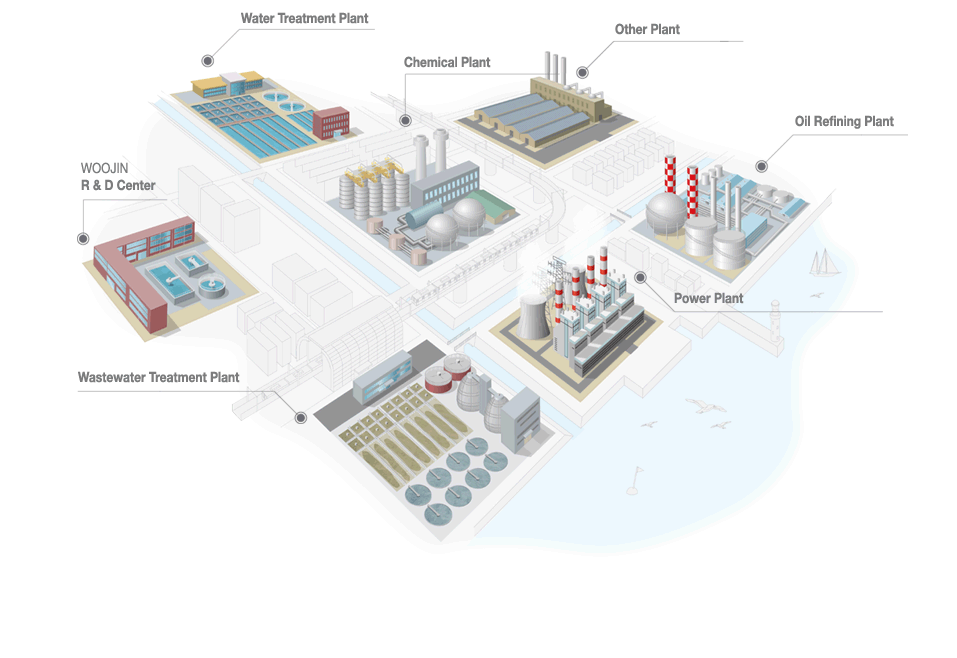

Water treatment, atmospheric environment, chemical, oil refining, food and etc….. We provide Total solution for Mixing required from each process.

|

|

We have the best technical team with years of various experience in Mixing Process design and we will provide the most suitable product (Mixer) for each process, mixing solution and process design upon your requests. |

|

|

||

|

||

|

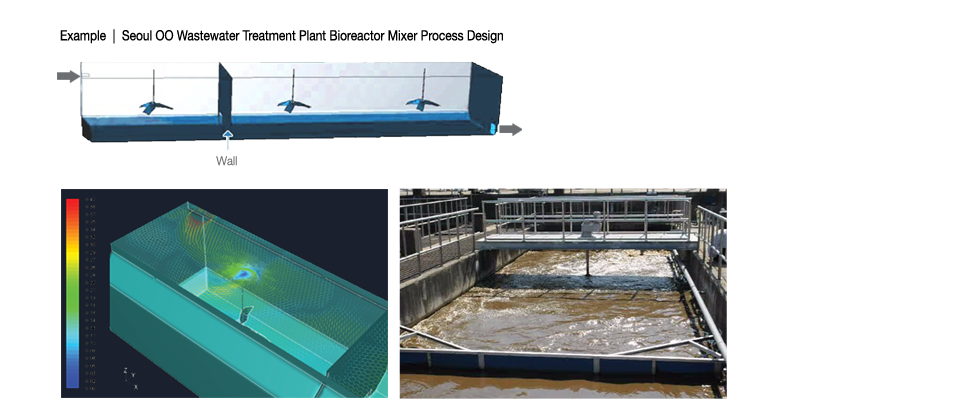

01. Tank configuration (including interval between PDF and number of PDFs) design considering retention time and mixing efficiency. 02. Channeling method and specification design considering fluid flow. 03. The optimum number and specification of mixer (Impeller type, revolution per minute, installation location, and etc) considering water quality characteristics and its process. |

||

|

|

||||||

|

After detailed diagnosis on your facilities with cutting edge measuring and analyzing equipments, we will develop improvement suggestion with diagnosis result so that your problem on mixing and process will be solved. 01. Result analysis after measuring mixing condition on operating facility. 02. Conduct computer simulation on facility and operating condition and analyze the result. 03. Develop improvement suggestion. 04. Verify design through computer simulation or pilot test. 05. Verify performance after improvement has applied. |

|

||||||

|

|

|||||||

|

|||||||

|

|

|

|

|||||

|

|||||||

|

|

|

|

|||||

|

|||||||

|

|

|

||||||

|

|||||||

|

|

|

||||||

|

|||||||

|

|

|

|

|

|

|

|

|